KREMERS URBAN PHARMACEUTICALS

Crothersville, Indiana

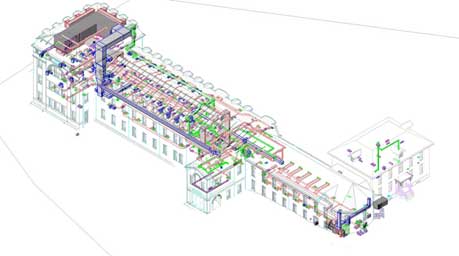

Mussett Nicholas Associates designed a $14 million R&D / QC Lab for a team of 50 employees. The facility included two labs, nine cleanroom processing units, and a full array of laboratory services including:

- RO Water Service

- Compressed Air

- Clean Air

- Nitrogen

- House Vac

- High-Pressure Vac

- Variable Speed Hoods

- Industrial Plant

- New Construction and Expansion

- 200,000 Square Feet