ELI LILLY CONTINUOUS MANUFACTURING ISPE – FOYA 2017 CLEAN ROOM

Indianapolis, Indiana and Carolina, Puerto Rico

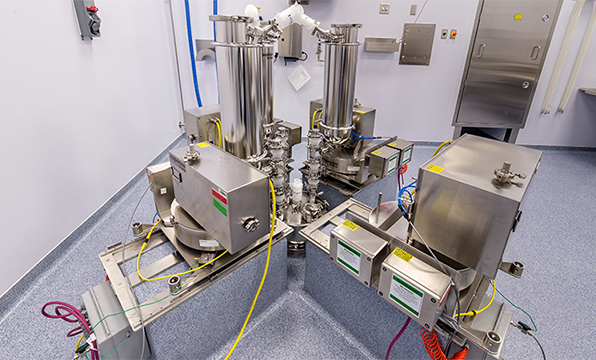

MNA served as the design team leader and worked with the Owner’s process development and construction team to implement a state-of-the-art continuous manufacturing suite at two different sites. The project consisted of designing a suite for the CDC (continuous direct compression) process equipment for OSD (oral solid dosage) products. Integration of the of the entire production process into a seamless and continuous flow was the goal of the project.

The first suite was built in Indianapolis, Indiana and served as the prototype project. The project team started with a blank sheet and developed every aspect of the layout, process flow, structure, and controls. Once the prototype was operational, work began on the second site in Carolina, Puerto Rico. Through a team approach and a focus on continuous improvement, the team was able to provide both the functionality and stability required for the sensitive control metering and measuring devices.

The project was ultimately recognized for its engineering effort by the International Society for Pharmaceutical Engineering in 2017. The project was the overall winner of the prestigious Facility of The Year Award (FOYA).

Design Team:

- MEP Designer: MNA

- Local Permitting: Babilonia Engineering Group

- Architect/Structural Design Partner: TLF, Inc.

- Construction Managers: Davis & Associates/Fluor Daniels Caribbean, Inc.

Key Metrics:

- 23,000-square-foot area | 4,500 square feet each

- 2014–2015 for designing

- 2015–2016 for construction

- Received the 2017 FOYA Overall Winner – ISPE award | Pharmaceutical Engineering Magazine